Fine Materials

For Assembly

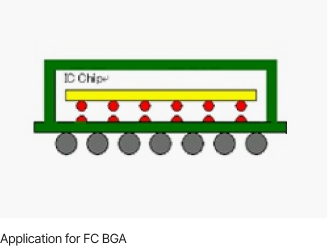

We have developed low alpha particle solder used for bumping in Flip-Chip IC(BGA,etc). Their alpha particles are successfully reduced to 1/100-1/1000 of generic solder by utilizing our long experienced refining and atomic power technology.

Solder material with

solution for soft error

Low Alpha-ray bumping solder

Mitsubishi Materials developed a low alpha-ray solder in which the counts of alpha-ray particles was successfully reduced to 1/100 _ 1/1000 compared to ordinary solders by utilizing our long experienced in refining and atomic power technology. These materials are used for bumping solder in flip-chip IC, e.g. CSP,BGA and so on.

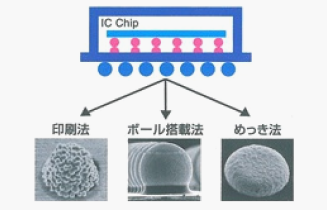

Bumping method and their characterization

| Solder Bump proess | Low-alpha solder products | Characterization | Availability | |

|---|---|---|---|---|

| Pb-Sn | Lead free | |||

| Ball | LA/ULA/SULA Solder Ball | good accuracy,high yields | ok | ok |

| Plate | A/ULA/SULA Liquid (Plating Solution) |

It is possible to make a lot of bumps for fine pitch at the same time. |

ok | ok |

| Paste | LA/ULA/SULA Paste | It is suitable to make large size bumps. |

ok | ok |

| Vapor evaporation | LA/ULA Pb, Sn LA/ULA Solder | Proven process, high yields | ok | ok |

| LA Grade | ULA Grade | SULA Grade | |

|---|---|---|---|

| Pb-Sn | ≤ 1.0cph/㎠ ≤ 0.3cph/㎠ |

≤ 0.02cph/㎠ 0.01cph/㎠ |

|

| Lead free | ≤ 0.01cph/㎠ 0.005cph/㎠ |

≤ 0.005cph/㎠ 0.001cph/㎠ |

Low alpha plating solution

Characterization

- Flat bump surface

- Uniform bump height and Sn composition

- High speed plating

- Long life

- Applicable to lead free

Alpha Grade

| Parameter | Pb/Sn : 95/05 | Pb/Sn : 37/67 | SULA Sn/Ag |

|---|---|---|---|

| Total metal content | 60 g/L min | 30 g/L min | 50 g/L min |

| Cathode current density | 2 - 6 A/dm2 | 2 - 6 A/dm2 | 2 - 5 A/dm2 |

| Bath temperature | 20℃ | 20℃> | 25℃ |

| Flow rate(Flow Rate) | 5 - 20 L | 5 - 20 L | 5 - 20 L |

| Anode type | Soluble/Unsoluble | Soluble/Unsoluble | Unsoluble |

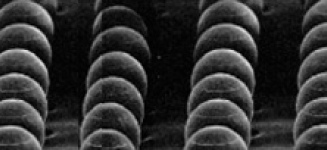

Photograph of bumps(Before reflow)

-

Eutectic solder bump m3069-574A1Pb/Sn=37/63

-

High lead solder bump M06005-571D0 Pb/Sn=95/05

Low alpha solder ball

composition

| Alloy | Composition |

|---|---|

| Pb-Sn | Pb-63%Sn, Pb-5%Sn |

| Lead free | Sn-3.5%Ag, Sn-1%Ag-0.5%Cu |

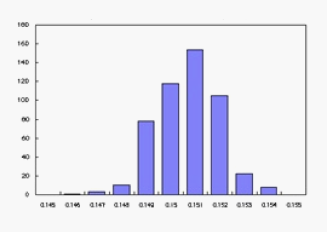

Diameter and tolerance of solder ball

| Diameter | Tolerance |

|---|---|

| 0.10, 0.15 | +/- 0.005 |

| 0.20, 0.25, 0.30 | +/- 0.01 |

| 0.40, 0.50 | +/- 0.02 |

(Unit : mm)

Low alpha solder paste

We can produce several systems, compositions and powder distributions for our customer’s needs

Composition

| Alloy | Composition |

|---|---|

| Pb-Sn | Pb-63%Sn, Pb-5%Sn |

| Tin-Silver | Sn-3.5%Ag, Sn-3%Ag-0.5%Cu |

Powder Diameter

| Classification | General Compsition |

|---|---|

| 5 - 40㎛ | 10 - 32㎛ / 5 - 15㎛ / 15 - 25㎛ |

Characterization

- A) Flux type

-

Activaterd Flux Flux contet chlorine Flux type R / RMA / RA 5 - 15% Cl<0.02 / 0.02>Cl>0.1 / 0.1>Cl>0.5

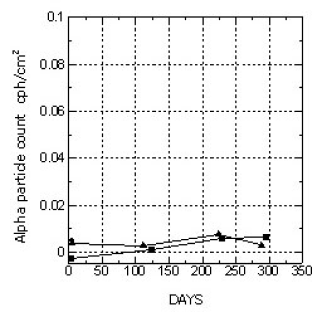

- B) Time variation of alpha emission

-

An example

Time variation of alpha emission of ULA Pb-63%Sn solder paste after reflow.

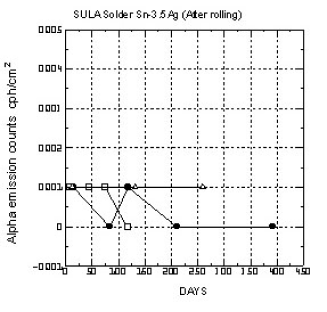

Super Ultra low alpha solder (SULA grade)

Regarding Sn-base solder, as we know, alpha particles are generated from radio isotopes,

like Pb (lead) However it is easily misunderstand that Sn-base (Pb free)

solder does not show any alpha emission problem, since it does not include lead.

So we developed super ultra low alpha solder for customer needs whose alpha level is very low.

Time variation of alpha emission of SULA Sn-3.5%Ag solder paste after reflow

Characterization

- Solder which correspond to alpha level < 0.002cph/cm2

- Solder which has no time variation of alpha emission. (Zero alpha emission solder)

Products

- SULA Liquid (Sn-Ag)

- SULA Solder paste (Sn-Ag, Sn-Ag-Cu)

- SULA Solder ball (Sn-Ag , Sn-Ag-Cu)